Asset management (AM) is one of the most important chapters in the operation of the power system (and energy system). Power system operations and AM activities are not always strongly linked. Operational decisions are mostly based on operational grid parameters such as voltages, currents and power flows at operational time horizon, whereas AM decisions condition the reliability of supply for several decades: AM decisions support tools and methodologies and support transmission and distribution grid operators to integrate the condition of their assets in their optimisation process to reduce capital and operational costs. Examples of asset conditions that can be monitored are temperature, moisture, dielectric strength, corrosion, gas mixture, oil health, dust, shadow, age, spare parts and maintenance availability, etc. From the perspective of the TSO, two central questions are how to make the best use of the assets over the asset lifetime and how to schedule the various asset management operations, especially for assets requiring outage for the duration of the operation.

Technology Types

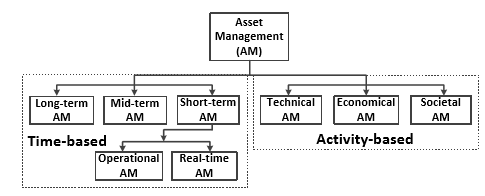

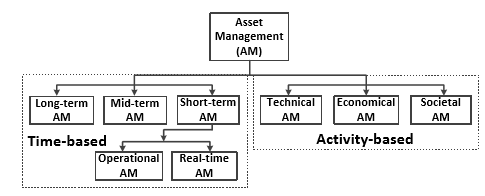

A classification of AM distinguishes at first time-based and activity-based AM.

The further subdivision of time-based AM includes the:

- Long-term (one year and beyond, encompassing future planning and investment on new assets or their upgrading).

- Mid-term (ranging a few months and involving the optimal scheduling of equipment maintenance and allocation of available resources with the aim of expanding the life span of existing facilities through proper maintenance), and short-term (categorised into operational asset management (daily and weekly).

- Real-time asset management (outage management). Operational asset management aims to minimise risks involved with assets, both physical and financial, due to load demand and hourly prices. Real-time asset management is also called the asset outage management and is based on contingency analysis which assesses the effect of unexpected outages.

The second activity-based category is split into technical-, economic- and societal-asset management. Technical AM deals with ageing, insulation and other physical conditions of assets. Socioeconomic analysis consider economic features (how AM would be influenced by financial constraints) and assesses the impact on society (that could be considered at large including environmental impacts: e.g. the impact of a failure and leak of SF6).

The distinction between maintenance and renewal action induces the difference between the corrective (carried out after failures occur) and preventive maintenance (carried out before failures occur).

Consequently, five types of AM emerge when considering the nature and maturity of the monitoring:

- Reactive monitoring analysis

- Time-based monitoring and analysis

- Reliability-based monitoring and analysis

- Condition-based monitoring and analysis

- Predictive monitoring and analysis.

Components & enablers

AM covers a wide range of domains including: maintenance strategies, determination of component condition, asset simulation and life assessment. Founding components are thus data and methods, complemented with sensor and monitoring equipment:

- The framework of data management upon which AM and maintenance strategies is built is an essential component.

- Methodologies to tackle the risk associated with AM include several approaches such as Value at Risk (VaR), Life Cycle Cost (LCC), Run–Refurbish–Replacement (3R’s), and various probabilistic approaches. In this category should be included all type of degradation and end-of-life mathematical models that support the AM policy.

- From the equipment standpoint can be mentioned all device, components, systems dealing with the data collection, management and processing chain and the knowledge management tool: asset health centre for the critical assets (transformer monitors, feeder monitors, circuit breaker monitors, power quality monitors); Instrumentation / sensors (moisture, temperature dielectric strength); Digitised protection and control re-lays; IoT and 5G for gathering and transmitting data from the sensors; Drones for advanced inspection; Big data analytics platform; Predictive analytics (AI) for distribution automation and transmission automation applications; AM decision software tools, including predictive analytics (AI) for equipment replacement and maintenance scheduling.

Advantages & field of application

Based on the data of monitored assets, AM methods simulate and detect asset degradation, allowing for adapted and optimised asset replacement. For example, AM systems may use correlation processing for AI to detect predictive asset degradation. The idea is to analyse real-time operational data from an active T&D grid device and compare the data to a library database of healthy similar devices, identifying any developing changes from normality that could become failures. This process allows comprehensive diagnostic systems to detect early failure patterns and prevent breakdowns before they occur. It has proven to be valuable in identifying operating conditions causing long-term performance issues.

Technology Readiness Level

There is a consensus that there is a strong need to develop and validate tools which address the lifecycle management of power (resp. energy) systems components, the scope includes ageing and degradation study to system diagnosis as it impacts both the CAPEX and OPEX of power (resp. energy) systems.

Deployment of IoT sensors, communication, data management & analysis and feedback to control systems: High TRL actions (TRL 7+) are expected in the next 2 – 3 coming years, including large demonstration actions aiming at reduced OPEX and optimised costs for AM.

Probabilistic AM methodologies based on risk evaluation are expected to have a longer term impact: AM policy assessment and outage scheduling are at a proof of concept stage (TRL 3) – laboratory testing (TRL 4) with a time to exploitation in the 2020-2025 time horizon.

Alternatives to human interventions will be studied and deployed: in the short term with data acquisition of power lines with drones that are fully competitive (TRL 8-9) and at a longer-time horizon with actions to validate the robotic replacement of live line working activities (TRL 4-5).

Research & Development

AM and maintenance is identified as Research Sub Areas 4.3 in the ETIP SNET R&I Roadmap 2020 – 2030 and in the ETIP SNET R&I Implementation Plan 2021 – 2024, and part of Research Area 4. Planning – holistic architectures and assets.

Current fields of research: Include the Integrated AM Approach; Augmented Reality; AI, Big data, Image recognition; Risk analysis in AM (Value at Risk), Life Cycle Cost, Run–Refurbish–Replacement (3Rs); Probabilistic methods for TSOs Reliability Management, mid-term and long-term asset management for TSOs (see GARPUR results on maintenance policy assessment, outage schedule assessment, modelling of the shorter-term reliability management).

Innovation priority to increase overall TRL: Expand enterprise asset managing performance programs to include greater connectivity between work processes and operation management tools.

The ETIP SNET R&I Implementation Plan 2021 – 2024 for transmission foresees the following R&I priority in relation to Asset Management: ‘Development of models for State-of-Health estimates of transmission system components (e. g., components wear, oil level in transformer oil pits, SF6 level in swithgear and probabilities of failure)’.

Best practice performance

When considering AM for TSOs, it remains very dependent on each TSO’s internal maintenance strategies and data framework. From the point of view of offer, providing a benchmark is complex due to the wide range of offers and their deployment to each particular context.

Best practice application

Description

Smarter Asset Management using Big dAta (SAMBA) is a 3-year industry innovation project headed by Statnett and supported by the Norwegian Research Council. The project has been researching the methods and methodology required to enable a transfer from asset management based on intervals to asset management based on the actual state of components in the power system.

Design

A variety of sensors were deployed from sensors to measure SF6 gas density, voltage transformer surveillance, cable temperature/pressure/moisture, oil health, transformer temperature, sensor motion in circuit breaker, dynamic line ratings sensors etc.. In addition, PMUs were deployed to measure frequency, current, voltage and phasors across the grid. A Wide Area Monitoring, Protection and Control System (WAMPACS) to integrate and analyse the PMU-data was implemented into the SCADA-system to get real feedback and experience. Dynamic models were developed to calculate the asset health probability of failures, criticality and risk indexes.

Results

A wide ranges of use cases were identified to improve monitoring and visualization of results, analysis of incidents and protection and control. In addition the operator saved on operational cost ~30-40% by going from preventative to predictive maintenance, annual capital cost of € ~ 50k by deferring replacement of transformers. Overall the operator was able to set up an ICT architecture suitable for asset management, demonstrate the need for sensors, measurements and data quality and built in-house expertise for condition monitoring models for power components.

Description

The MANINT program 2017 – 2020 developed by Red Eléctrica de España. The project aims at developing optimized maintenance techniques for the HV assets to increase the grid availability and reduce costs.

Design

By applying digital technologies, data analytics and proper user interfaces, the reactive and preventive maintenance turns into predictive and cognitive maintenance. Key elements to achieve this transformation and transit to a fully optimized maintenance schedule is the data monitoring, the use of the asset health index and asset risk index.

Results

Benefits are expected in several domains: technical, management, economic and environmental. It is a conceptually natural extension of this system to become a predictive maintenance, which further improves efficiency and reliability. This will reduce maintenance costs and extend asset lives.

United States

Research started in 2012

Description

Public Service Electric and Gas Company (PSE&G) employs advanced analytics on real-time sensors to track various operational metrics.

Design

PSE&G uses analytics to generate a condition score for transformers based on multiple factors, such as moisture, dielectric strength, combustible gas rate of change, and cooling performance. An asset replacement (predictive) algorithm uses this condition score, and other factors (chronological age, spare availability) to determine the appropriate time to replace transformers.

Results

Usage of analytics has helped the company in identifying problems and remediating issues before a failure, saving millions of dollars in equipment failure avoidance. The company has also determined that replacing some transformers proactively (by using analytics models), rather than reactively, will help it save over $100m over a 25-year period.

References

[1] TD World. Asset Health Awareness Changing the Grid. [Link]

[2] Capgemini Consulting. Big Data BlackOut: Are Utilities Powering Up Their Data Analytics? [Link]

[3] Cired. Incorporating Asset Management Into Power System Operations. [Link]

[4] ABB Asset Health Center, End-to-end asset management that turns ‘big data’ into clear and actionable intelligence. [Link]

[5] Wan S. Asset Performance Management for Power Grids. [Link]

[6] ABB. Asset Health Center. [Link]

[7] Red Electrica. Sustainability Report. [Link]

[8] Statnett. Statnett's R&D Conference 2019. [Link]

[9] Stattnett. Asset Management with artificial intelligence. 2019. [Link]

[10] Stattnet. Metrologicalchallenges in the future Transmission Grid.

[11] TUDELFT. S. Khuntia. Article published in FP7 GARPUR project. A literature survey on asset management in electrical power [transmission and distribution] system. [Link]

[12] TUDELFT. S. Khuntia. Article published in FP7 GARPUR project. Classification, domains and risk assessment in asset management A literature study. [Link]

[13] GARPUR outputs. [Link] and in particular deliverable D5.1 Functional analysis of Asset Management [Link] and deliverable D5.2 Pathways for mid and long-term Asset Management. [Link]

[14] GARPUR booklet, pages 14-15 on asset management. [Link]

[15] ETIP SNET R&I Roadmap 2030. [Link]

[16] ETIP SNET R&I Implementation Plan 2021-2024. [Link]